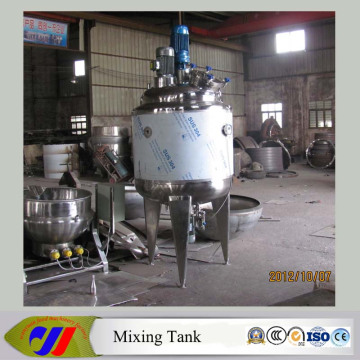

1500L Stainless Steel Steam Heating Cosmetics Mixing Tank Emulsification Machine

Basic Info

Model No.: WY-100

Product Description

Model NO.: WY-100 Customized: Customized Composition: Mixing Machine Process: Thermal Processing Material: Ss304/316L Structure: 3 Layer, 2 Layer or 1 Layer Specification: CE ISO Condition: New Voltage: Can Be Customized Processing Material: Natural Ingredients Heating Method: Electric Heating and Steam Heating Agitator Type: Anchor Frame Impeller Magnetic etc Mixing Speed: 36/60/120/2800rpm Origin: Wenzhou China 1500L Stainless Steel Steam Heating Cosmetics Mixing Tank Emulsification machine

Name: Stainless Steel Mixing Tank

Automation: Manual, semi-automatic, full-automatic

Capacity: 100-1000L

Suitable Temp.: 0-100 ºC or higher upon requirement

Power: 380V/50HZ/3Phase or customized

Control System: Push button/PLC/touch screen; Optional

Material: SUS 304/316L optional

Structure: 3 layers(inner bladder, jacket, insulation layer), 2 layers, 1 layer upon requirement

Surface: Inner/outer polished, outer: Drawbench polished

Stirring method: One direction mixing or two direction(optional)

Stirrer type: Can be selected from anchor type, impeller type, frame type, high speed shear, magnetics type and etc.

Application: Can be used to mix and melt all kinds of materials in industries like pharmacy, cosmetics, chemicals, resins, paintings, confectionary, pigments and etc.,

Mixing tank Machinery Range

Stainless steel mixing/melting/storage tank series

Homo and vacuum mixing tank

Softgel capsule production line supportive machinery

Pharmaceutical CIP&SIP system

Herbal Extraction and concentration/evaporation machinery

Mixing tank Features

A full range of products to specifically meet client production need

With high technology and advanced automation

Fully meet the standard of GMP and CGMP

Overall service from consultation, design, manufacturing, installation, operation and training

Our Mixing tank capacity can be 50L, 200L, 500L, 2000L or any other capacity you need.

Contact us if you need more details on Mixing Tank. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Liquid Mixing Tank、Conical Bottom Mixing Tank. If these products fail to match your need, please contact us and we would like to provide relevant information.

Name: Stainless Steel Mixing Tank

Automation: Manual, semi-automatic, full-automatic

Capacity: 100-1000L

Suitable Temp.: 0-100 ºC or higher upon requirement

Power: 380V/50HZ/3Phase or customized

Control System: Push button/PLC/touch screen; Optional

Material: SUS 304/316L optional

Structure: 3 layers(inner bladder, jacket, insulation layer), 2 layers, 1 layer upon requirement

Surface: Inner/outer polished, outer: Drawbench polished

Stirring method: One direction mixing or two direction(optional)

Stirrer type: Can be selected from anchor type, impeller type, frame type, high speed shear, magnetics type and etc.

Application: Can be used to mix and melt all kinds of materials in industries like pharmacy, cosmetics, chemicals, resins, paintings, confectionary, pigments and etc.,

Mixing tank Machinery Range

Stainless steel mixing/melting/storage tank series

Homo and vacuum mixing tank

Softgel capsule production line supportive machinery

Pharmaceutical CIP&SIP system

Herbal Extraction and concentration/evaporation machinery

Mixing tank Features

A full range of products to specifically meet client production need

With high technology and advanced automation

Fully meet the standard of GMP and CGMP

Overall service from consultation, design, manufacturing, installation, operation and training

Our Mixing tank capacity can be 50L, 200L, 500L, 2000L or any other capacity you need.

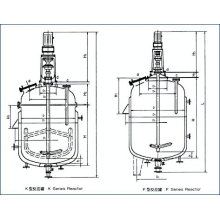

| volume (L) | Dimension (D× h ) (mm) | Total height (mm) | Diameter Of inlet & outlet | Heat preservation layer (mm) |

| 500 | 840 × 1000 | 2250 | 38 | 60 |

| 600 | 920 × 1000 | 2300 | 38 | 60 |

| 700 | 990 × 1000 | 2300 | 38 | 60 |

| 800 | 950 × 1220 | 2500 | 38 | 60 |

| 900 | 1010 × 1220 | 2500 | 38 | 60 |

| 1000 | 1060 × 1220 | 2550 | 51 | 60 |

| 1500 | 1160 × 1500 | 2850 | 51 | 60 |

| 2000 | 1340 × 1500 | 2900 | 51 | 60 |

| 3000 | 1410 × 2000 | 3400 | 51 | 60 |

| 4000 | 1620 × 2000 | 3450 | 51 | 60 |

| 5000 | 1810 × 2000 | 3500 | 51 | 60 |

Product Categories : Beverage Processing Machinery

Premium Related Products

Other Products

Hot Products

Fs-600 Lunch Box SealerMini Milk Turnkey Processing PlantDurable and Practical Food Vacuum Packing Mahchine for Vegetable and Fruit (DZ-600)50 Liters Stainless Steel Milk CansSweet Corn Thresher, Corn Threshing MachineSterilizer for Ham Sausage (Autoclave Sterilizer Retort)Peanut Peeling Machine, Almond Skinning MachineElectric Cooking Pot Jacketed Cooking Kettle (DG200)New Product Steam Heating Sandwich Pot with Scraper1000 Liters Capacity Autoclave Sterilizer Retort for Canned FoodIndustrial Stainless Steel Eletric Garlic Bulk Separating Breaking Machine Equipment (FX-139)Automatice Type Sausage Filling Machine/ Sausage padding MachineFish Cutter High Speed Cutter (Squid Ring Cutter)Vegetable De-Water Machine, Vegetable Centrifugal DehydratorLarge Type meat mincer machineDesk Type Meat Mince Machine